Upgrades

Keep your operation running

safely, efficiently, and profitably.

Taking advantage of upgrades ensures that you don’t incur project impacts or product loss due to malfunction, wear, or unscheduled maintenance. In some cases, upgrades allow you to replace manual processes with automation to increase quality, consistency, and volume.

Upgrades are an ideal way to add features to your equipment that would otherwise only be possible by replacing them. Windows 10 computer upgrades, along with various modernization packages including dust-tight chutes and air reject systems, are some ways that you can update your tablet press from worn and aging to state-of-the-art.

Some benefits of upgrading your tablet press:

- Higher productivity and reduced production costs. Specific adjustments will bring tablet presses up to the latest level of technology. The decisive advantage of upgrading older tablet presses is the definitive increase of efficiency at clear calculable costs.

- Improved user-experience. Central user management on both operating system and network levels.

- Increased product quality. Upgrading with dust-tight chutes or air reject systems allow for higher process security and can reduce waste.

- Optimized supply of spare parts. Keeping your machine up-to-date allows for quick and easy order processing of spares, as all obsolete components are replaced with the newest offerings.

- Prolonged service life. Maintaining the tablet press in good workable condition, as well as upgrading with new offerings ensures an extended overall service life. For example, upgrading to stainless steel Fill-O-Matics resists scratches, chips, and other daily wear damage. The casting and base plates have a superior finish for micro testing and quick cleaning.

- Easier cleaning. Upgrading your tablet press with certain components enables rapid changeover and quick cleaning, which increases output and lowers the risk of cross-contamination.

- Increased yields. If you seek to run a state-of-the-art machine that can achieve 99% yields, you need to consider an upgrade.

Some warning signs that indicate losing functionality:

- Downtime. More frequent downtime is a key performance indicator that shows your tablet press is no longer working efficiently and is due for an upgrade.

- Noticeable wear/damage. As your tablet press ages and experiences signs of wear, replacement parts may no longer be available. An upgrade can modernize your equipment, bringing components and software up to the latest versions.

- Filling difficulty. As your tablet parts age, you may start to notice decreased production and increased waste. Upgrades increase filling accuracy, reliability, and efficiency.

Rebuilding or upgrading –

what's the difference?

Upgrading modernizes your tablet press and replaces obsolete tablet parts with updated parts for added functionality and longer service life.

A factory rebuild restores your tablet press to original factory conditions.

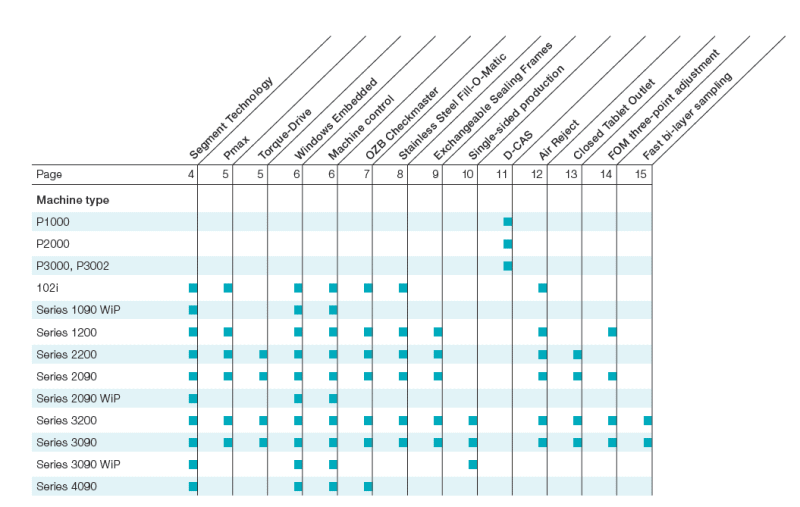

There are many options for upgrades, depending on your issues or goals. Upgrade options include:

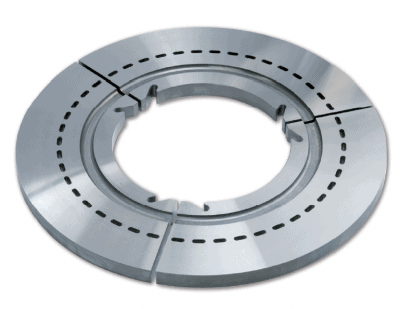

Introducing segmented technology speeds up changeover and setup times to optimize output. This innovative technology offers unmatched performance potential while also reducing the risk of cross contamination when changing products, as well as reducing product loss, thanks to the smooth surfaces and lack of rough edges.

Checkmaster and AutoTest systems are upgrades that validate that weight, diameter, thickness, and hardness conform to specifications immediately after compression. Both are available with optional feedback loops for additional process security.

Similarly, air reject upgrades enable automatic rejection of tablets that don’t conform to tolerances, increasing quality, accuracy, and yield.

Older operator interfaces are not always intuitive. With HMI upgrades for Windows operating systems, the terminal is replaced with a more user-friendly design. The upgraded central user management interface performs automatic documentation of product and batch activities, resulting in streamlined operations.

Fette Compacting is a global company specializing in leading-edge tablet machinery, parts, tooling, services, training and upgrades for existing machines. With our tablet press upgrades, you can modernize your tablet press machine with the most up-to-date components and state-of-the-art features.

For more information, or to get started on your upgrade solutions:

Segment Technology.

Fette Compacting’s innovative segmented technology offers unmatched performance potential. Reducing cleaning and set-up time while also reducing the risk of cross contamination when changing products, makes this a sound investment. As an added bonus, segments can help reduce your product loss thanks to the smooth surfaces and lack of rough edges.

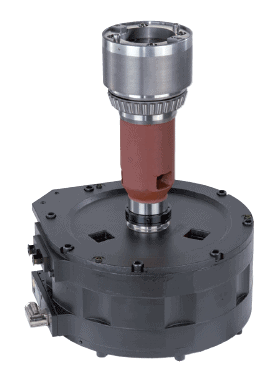

Pmax Turrets.

How do you increase your tablet output for small tablets while being able to control individual tablet rejection? With Fette Compacting’s exclusive Pmax technology for FS12® tooling.

Offers:

- Identical filling and dwell times

- Smooth machine operation

- Single compression force measurement

- Precise ejection of bad tablets

- Reduced wear and cost

- Familiar production parameters and features

Torque Drive.

Installing a direct torque drive on your existing Fette Compacting tablet press introduces a range of advantages that results in higher profitability and improved working conditions. Benefits include significantly lower current consumption, high torque, particularly at high speeds, no consumable parts, no expensive service work, and smooth running of the tablet press.

Windows Embedded and DC2-Windows.

Increase your work reliability with the Windows Embedded and DC2-Windows software. Windows 7-Embedded offers easy integration of new software developments by simplifying operations, increasing flexibility and increasing process reliability. Some features include central user management, on both operating system and network levels, as well as complete documentation of product change.

OZB Checkmaster.

Satisfy your demand for efficiency and upgrade to the OZB Checkmaster. By precisely measuring the weight, height, diameter, and hardness of a tablet this mechanism helps log a complete batch of data. Along with an automatic in-process control and easy conversion of existing instruments, the OZB Checkmaster can reduce modification costs and increase process security.

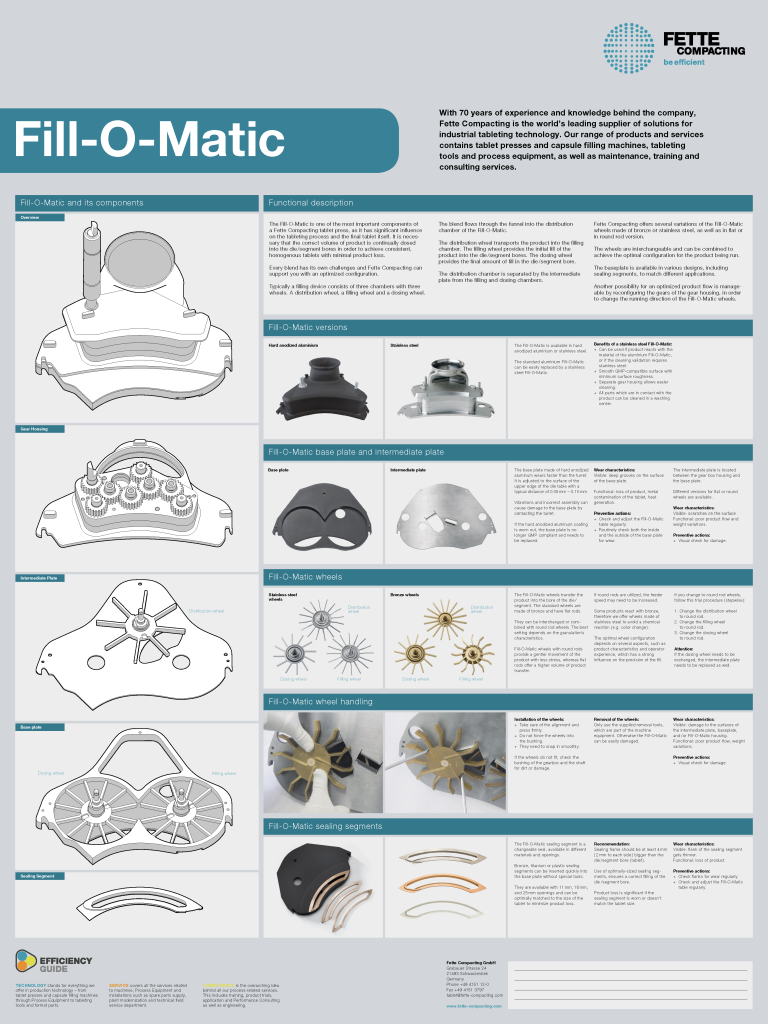

Stainless Steel Fill-O-Matic.

Reduce your product loss with the stainless steel Fill-O-Matic, which has a 3-chamber system (i.e. filling-, distributing- and dosing wheels). GMP-compatible surfaces allot for easy and fast cleaning with minimal surface roughness.

Fill-O-Matic

Exchangeable Sealing Frames.

Fette Compacting’s goal is to develop simple tools for efficient production. The Fill-O-Matic baseplate with exchangeable inserts is fast and easy to dismantle without tools. Three different sizes of sealinginserts (11 mm, 16 mm, 25 mm) are available in bronze or PETP and can be matched for use to specific tablet sizes. Powder filling is optimized, conversion times are shortened, process security is increased, and product loss can be reduced.

Adjustment for older tablet presses can be simplified from four adjustment points to three. Set-up and downtime after a product change will be reduced, as well as the overall changeover time.

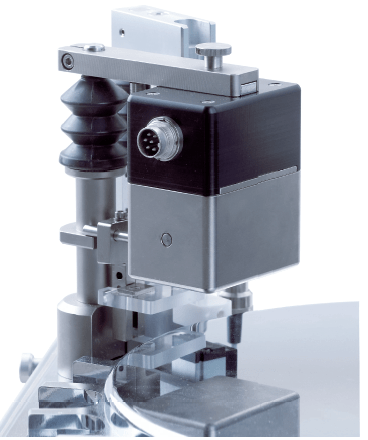

Air Reject.

Fette Compacting’s product-saving air reject features immediate rejection at the die table for early elimination of bad tablets. Along with a long lifespan, down-time is reduced, the rejected tablets remain undamaged and a post-rejection analysis is provided. This device is particularly suitable for very small tablets, very light tablets, and sophisticated shapes. Depending on machine model type, our air reject is available with the air curtain feature for precision tablet rejection.

Dust-tight Tablet Chute.

Leading edge technology, such as the dust-tight tablet chute, reduces dust levels, shortens conversion times, and increases process security. The separate controller and discharge unit with non-contacting magnetic drive can reduce the wear. Plus, the discharge unit is completely enclosed with food-grade acrylic housing. All product parts can be machine cleaned and are fast and easy to dismantle without tools.

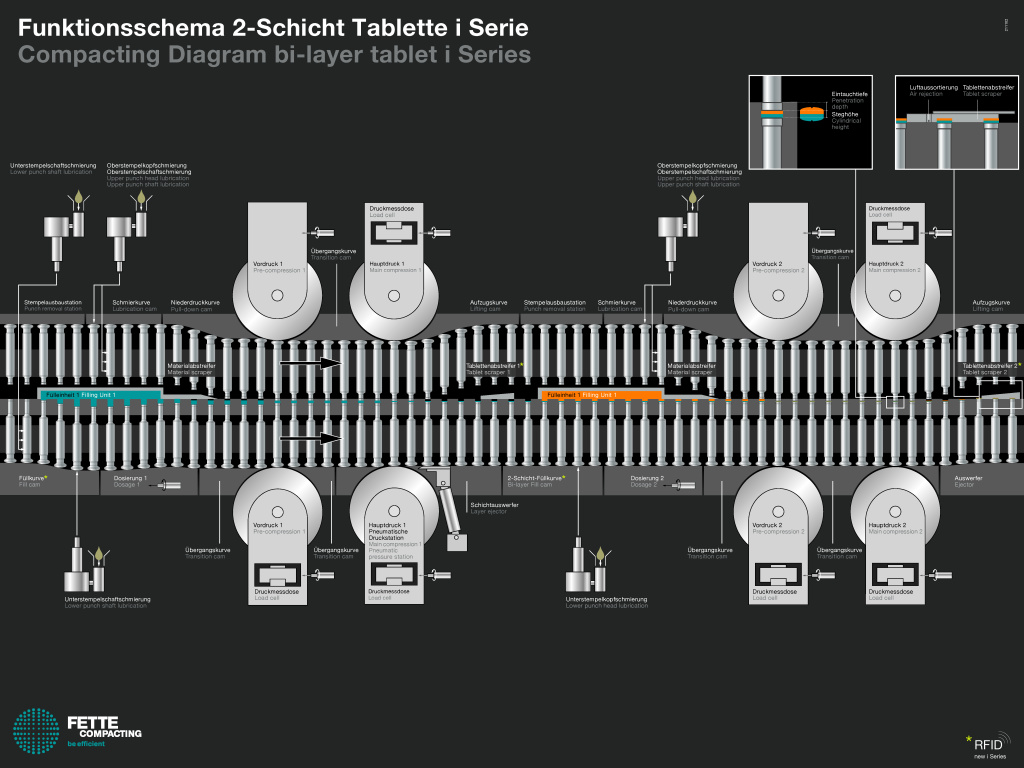

Fast

Bi-layer Sampling.

Fast sampling of first layer will improve the automatic in-process control for bi-layer tablets. Fette Compacting’s pneumatic ejector can reduce sampling time by up to 80% and minimize production loss.

You have questions about

our Upgrades?

Fette Compacting America, Inc.

400 Forge Way Rockaway

N.J. 07866 USA

Related Topics.

Check out Fette Compactings resources section for informational eBooks, guides, and videos that can help you make the most of your tablet press.