To ensure the production of high quality product, to minimize downtime, and to maximize your investment in the industry-leading press you own, Fette Compacting recommends training for all of the people responsible for maintaining and running your tablet press.

Training

More than just pressing the

start and stop button.

Level Based Certification Training

Level Based Certification Training

Certification assessments

To this end, Fette Compacting requires that all participants achieve a 100% score on both the written and practical assessments, to be administered at each level. To help meet the needs of individuals on all learning levels, we will allow the use of hand written notes and other training materials to be used during the written and hands on portions of the certification assessments. Achieving the full certification would require successfully completing all five levels, which would approximately take three weeks. However, it is not a mandatory requirement that the levels be completed in direct succession. For learning purposes and to ensure that each participant receives individual attention, Fette Compacting will limit the total number of participants per class to six (6) attendees per class.

The total System Controller (TSC) has been configured with security levels reflective of the corresponding levels of certification. As the requirements of each level are successfully met, the appropriate security access will be granted.

To find out more information please call 973-586-8722 and ask for Bill Garneau.

Training

programs.

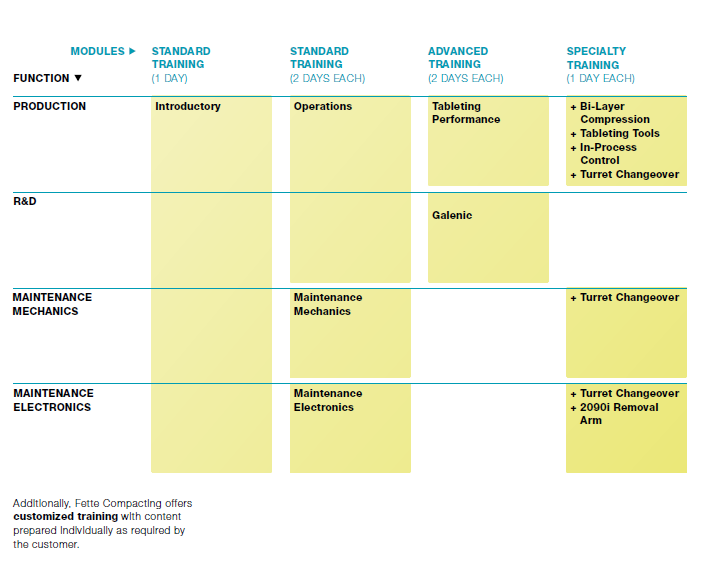

Thanks to our modular range of training programs, employees in production, technology, maintenance, development, and even cross-sectoral departments can be trained in their specific areas relevant to production. Individually compiled training sessions are also available and can be customized to your needs.

Introductory Course

Length of time:

2 days

Audience:

Maintenance Staff (Mechanical)

After this training course, you will be capable of safely handling the machine and the tasks associated with it. You will systematically remedy errors and carry out professional maintenance.

- General Settings

- Wear Parts

- Reference Marks

- Zero Balance

- Lubrication System

- Sorting System

- Rotor Clamping System

- Practical Exercises

Operations

Length of time:

2 days

Audience:

Operators, Machine Setters, Quality Managers, Technologists

After this training course, you will be capable of safely handling the machine and the tasks associated with it. You will manufacture tablets to pre-set specifications and independently perform minor optimizations in production. Furthermore, you will learn how to detect early on any possible signs of wear and how to prevent it.

- General Settings

- Production Parameters

- Formulation Setup

- Production Setup

- Compression Force Control

- Sorting System

- Wear Parts

- Initial Troubleshooting Skills

- Practical Exercises

Maintenance Mechanics

Length of time:

2 days

Audience:

Maintenance Staff (Mechanical)

After this training course, you will be capable of safely handling the machine and the tasks associated with it. You will systematically remedy errors and carry out professional maintenance.

- General Settings

- Wear Parts

- Reference Marks

- Zero Balance

- Lubrication System

- Sorting System

- Rotor Clamping System

- Practical Exercises

Maintenance Electronics

Length of time:

2 days

Audience:

Maintenance Staff (Electronic)

After this training course, you will be capable of safely handling the machine and the tasks associated with it. You will systematically remedy errors and carry out professional maintenance.

System & Component Overview

Network & CAN-Bus

Safety PLC

Reference Marks

Zero Balance

Lubrication System

Drives

Fault Finding

Battery Exchange (only i-Generation)

Practical Exercises

Tableting Performance

Length of time:

1-2 days

Audience:

Experienced Operators, Developers, Quality Managers, Technologists

After this training course, you will be experienced in safe handling of the machine and the tasks associated with it. You will systematically remedy production errors and independently carry out performance-optimized processes. Customized training with selected content such as:

- Eliminate Quality Issues (e.g. Weight Variation, Tablet Contamination, Sticking, Capping, Laminating)

- Optimize Product Flow

- Minimize Product Loss

- Increase Output

Galenic

Length of time:

2 days

Audience:

Experienced Operators, Developers, Quality Managers, Technologists

After this training course, you will be capable of safely operating Fette Compacting Galenic software and generating graphics (force-way diagrams).

- Machine Adjustment

- Single-Punch Pressing

- Production of Multi-Layer Tablets

- Using the Galenic Software

- Practical Exercises

Bi-Layer Compression

Length of time:

1 day

Audience:

Experienced Operators, Developers, Quality Managers, Technologists

After this training course, you will be capable of safely handling the machine and the tasks associated with it. You will manufacture 2-layer tablets to specifications and independently perform minor optimizations in production.

- Functional Principle of Bi-Layer Tablets

- Mechanical Modifications of the Press

- Parameters of Bi-Layer Relevance

- Bi-Layer Product Setup

- Practical Exercises

Tableting Tools

Length of time:

1 day

Audience:

Operators, Machine Setters, Quality Managers, Technologists

After this training course, you will be familiar with the various manufacturing standards for tools. You will know how tools are cleaned, maintained and stored. This will enable you to reduce downtimes and improve machine availability.

- Manufacturing Standards

- Coatings

- Dies & Segment Technology

- Handling, Cleaning, Polishing & Inspection

- Defect Analysis

- Practical Exercises

In-Process Control

Length of time:

1 day

Audience:

Operators, Maintenance Staff, Developers, Quality Managers, Technologists

After this training course, you will be capable of correctly setting the in-process parameters and evaluating the respective protocols. You will be able to clean, maintain and operate the tablet tester. Furthermore, you will master operation of the control loops for tablet weight and breaking strength.

- Mechanical Construction

- Operation

- Process-Relevant Parameters

- Tablet Weight & Hardness control

- Practical Exercises

Turret Changeover

Length of time:

0,5 day

Audience:

Operators, Maintenance Staff, Machine Setters, Technologists

After this training course, you will be capable of safely and quickly changing the turret. This will enable you to reduce conversion times and improve machine flexibility.

- Installation & Removal of a Turret

- Practical Exercises

2090i Removal Arm

Length of time:

0,5 day

Audience:

Maintenance Staff

After this training course, you will be capable of safely handling the removal arm. You will be able to adjust electronic boundaries and traverse paths. This will enable you to reduce conversion times and improve machine flexibility.

- Position & Functional Principles

- “Teaching” of the Removal Position

- Practical Exercises

You have questions about

our Trainings?

Fette Compacting America, Inc.

400 Forge Way Rockaway

N.J. 07866 USA

Related Topics.

Check out Fette Compactings resources section for informational eBooks, guides, and videos that can help you make the most of your tablet press.