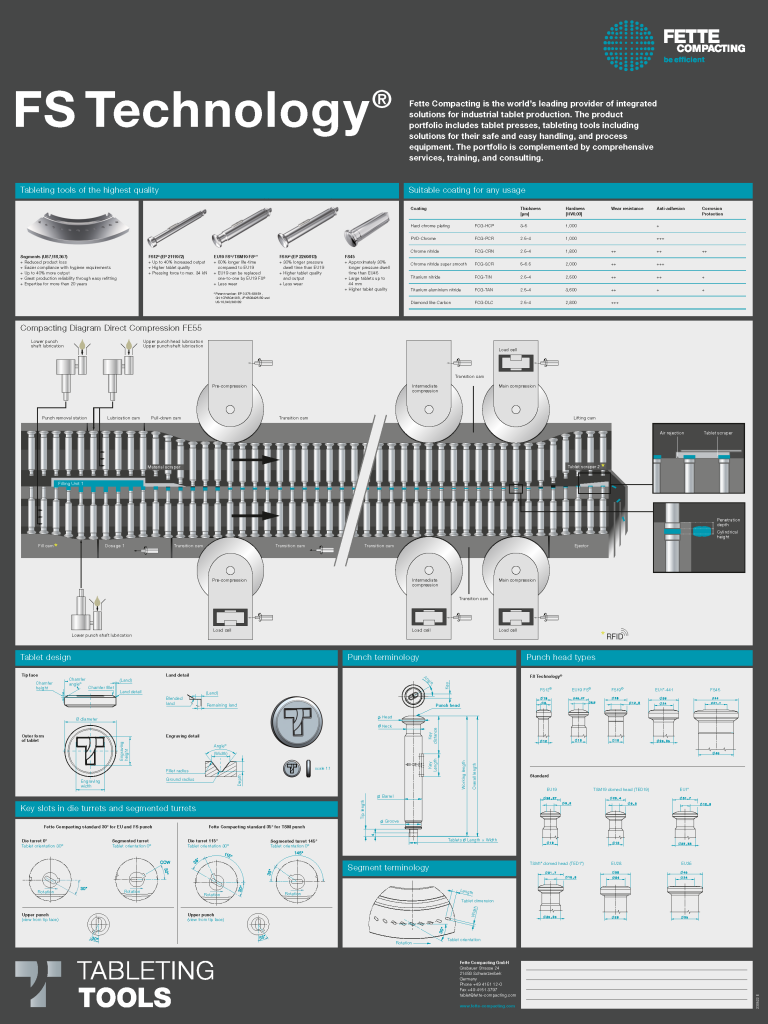

Tableting Terminology.

The experts at Fette Compacting have compiled this glossary of tableting terminology to familiarize users with the words and phrases they may encounter when using tablet presses.

Barrel

The punch tooling’s vertical bearing surface, which contacts punch guides within the machine turret to control vertical movement. Barrel length and diameter will vary depending on the dimensions of the turret press.

Barrel-to-stem radius

A radius measurement on the tooling at the point where the punch barrel blends to the stem. This curved area acts as a transition between the barrel and tip length.

Cup depth

A measurement of the cup depth between the deepest point of the cup cavity and the highest point of the tip edge. The tooling’s cup depth determines the size and appearance of the tablet. Wear and tear on the cup will change its depth and alter the appearance and configuration of produced tablets.

Cup land

The area separating the outside diameter (OD) of the punch tip and the edge of the punch cup. The cup land imparts additional strength to the tip of the punch to prevent cracking or fracturing.

Die

The cavity where the tablet is compressed and formed into a specified tablet shape. The shape and size of the die bore ultimately determine the size and shape of the formed tablet.

Direct compression (DC)

A method of tablet formulation that involves mixing raw material powders into an evenly distributed blend and applying compressive force to create tablets. Direct compression has become one of the most popular methods for tablet formulation due to its cost-effectiveness and convenience.

Punch Head

Comes into direct contact with the cam track on the machine and transfers pressure for tablet compression. The head flat relates directly to the length of the compression process for each tablet, with a longer dwell time typically yielding more stable tablets.

Multi-tip tooling

Used with dies or segmented turrets to provide extreme precision for micro-tabs and specialty applications. Multi-tip tooling is also used to increase overall tablet output.

Punch length

There are two punch length measurements:

- The overall length (OL) measures the punch from the tip’s end to the head flat.

- The working length (WL) measures the punch from the head flat to the deepest point of the punch cup.

Punch tips

Punch tips determine size, shape, and profile of the produced tablet.

Stem

The portion of the punch opposite the punch head, between the punch tip edge and the barrel.

Tableting

An umbrella term encompassing any of the methods used to compress powdered materials into solid tablets.

Tip face

The portion of the tip containing embossed lettering or designs, which then gets pressed into the tablet. The amount of text or size of a design or logo allowed per tablet is proportionate to the size of the tip face.

Tooling

An umbrella term for the entire custom toolset used to produce a tablet, consisting of the die or segment, lower punch, and upper punch.

Do you have questions?

We would be happy to provide you with further information and in-depth advice.

400 Forge Way Rockaway

N.J. 07866 USA